System coordination includes commissioning and integrated testing of fire alarm systems using NFPA 3 and NFPA 4 as guidance.

- Analyze NFPA 3 and NFPA 4, and how they relate to commissioning and testing fire protection systems.

- Know the steps to commissioning and testing fire alarm systems.

- Apply NFPA 3 and NFPA 4 in the design of a coordinated fire protection system.

Over the past decade, building design and construction has undergone a transformation of sorts. Gone are the days of individual standalone systems, designed in a vacuum by isolated design professionals from the various disciplines, with coordination limited to making sure equipment fit into the spaces allotted for it.

Today’s building designs emphasize system integration to achieve sustainability and efficiency goals. While this makes for a more stimulating design and construction effort, with professionals from all disciplines engaged to achieve much more lofty goals for the facility, it also requires foresight in the early stages of a project to develop a strategy and process to confirm that not only single systems are operating as intended, but also that system coordination is attained at the end of construction.

Commissioning and integrated testing are two different concepts, though both are needed to properly evaluate the operation of a fire alarm system and confirm that it interacts properly with other systems. In practice, the two are not necessarily inclusive. A commissioning authority (CxA) is responsible for the commissioning of individual systems, such as the fire alarm system, and does not evaluate interaction with other systems. An integrated testing agent (ITa) plans and executes the integrated testing of interconnected systems. The CxA and the ITa are not required to be the same entity.

However, a company or person who has qualifications of both fire alarm commissioning and integrated testing can provide both services, which is a good practice that also increases efficiencies. For the sake of simplicity in this article, the CxA and the ITa are considered to be the same person or company-one that is qualified to serve both roles simultaneously.

Commissioning has many definitions. The focus is on the commissioning and integrated testing of fire alarm systems, so the definition from NFPA 3 seems most appropriate:

A systematic process that provides documented confirmation that building systems function according to the intended design criteria set forth in the project documents and satisfy the owner’s operational needs, including compliance with applicable laws, regulations, codes, and standards.

This definition summarizes the intent of commissioning efforts while highlighting the overall intent of the process: the assessment and documentation that systems operate as intended by design and meet owner’s needs as well as applicable code and standards. It is very important to note the distinction that commissioning determines that systems meet design criteria and code requirements as well as satisfy owner needs. CxAs are ultimately working on behalf of the owner’s best interest and need to keep that fact in mind throughout the project.

The fire alarm system hub

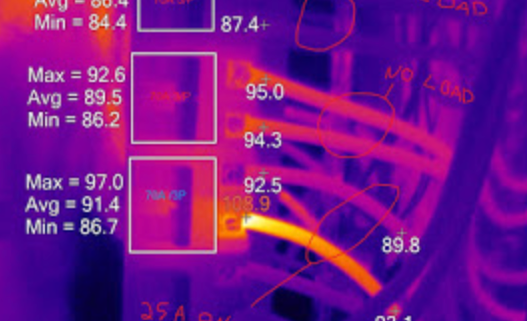

Building commissioning efforts are far-ranging, with evaluations for all building systems as well as their interaction with other systems to meet facility objectives. As a result, fire alarm commissioning represents a small portion of the overall whole. Despite its relative scope in relation to other systems, however, the fire alarm system is critical to the building operation and typically requires coordination with many other facets of the building commissioning. In most buildings, the fire alarm system acts as a central hub of information gathering and distribution, especially with respect to other fire protection and life safety systems. Consider for a moment some of the building systems with which the fire alarm system may communicate, depending on the type and scale of the building (see Figure 1):

- Alarm notification

- Building management systems (BMS)

- Elevator systems

- Emergency communication/notification systems

- Emergency power

- Fire suppression systems

- Gas detection

- HVAC systems

- Security and access control systems

- Smoke control systems.

This is not an exhaustive list, as buildings with special hazards or occupancies will have additional systems that may interface with the fire alarm system. Process equipment in industrial facilities may coordinate shutdown procedures with the fire alarm systems under specific scenarios. Assembly spaces, such as theaters and performance halls, may interface with the fire alarm system to terminate audio in the room and bring up house lighting upon certain circumstances to provide orderly evacuation.

The point is that although the fire alarm system is a single system within a building, its interaction with other systems is now extensive. It is no longer a control panel at the entrance to the building, communicating with alarm-activation devices, supervising a few sprinkler system control valves, and activating occupant-notification appliances. Mapping and confirming the flow of information to and from the fire alarm system and identifying its interactions with other systems can be a complex and daunting undertaking. The CxA for the fire alarm system must, therefore, not only understand that system, but also be able to recognize and comprehend the extent and intent of the interplay with other systems under all scenarios and then capture it all in the commissioning effort.

Fire alarm commissioning/testing

In an ideal world, the fire alarm commissioning and integrated testing effort would be established and coordinated at the start of the design of a project and follow the systematic approach documented in NFPA 3 and NFPA 4. That approach is summarized below:

- Review and assist in final development of the owner’s project requirements (OPR) document, which establishes the design objectives and goals of the systems.

- Review and provide input on the basis of design (BOD) report, which records the specific design strategy for each system.

- Perform design reviews throughout the project to evaluate the design and sequence of operations against the BOD.

- Develop a commissioning plan, which is a living document detailing the commissioning process and tests required as part of the commissioning. The commissioning plan should include a commissioning schedule, which is evaluated and updated periodically as the project progresses.

- Develop an integrated test plan, which identifies the specific tests that will be conducted for each system, including the interaction of systems as required to confirm that the building will operate as intended and meet the objectives.

- Review and verify that shop drawing/equipment system submittals are in conformance with the BOD.

- Perform regular inspections during installation to verify compliance with design and approved system submittal documents.

- Perform system testing in accordance with the commissioning plan and prepare documentation. Follow-up testing and inspections may be necessary to

- Prepare the commissioning report, which is a comprehensive database of all information developed during the full commissioning process.

- Perform system testing in accordance with the integrated testing plan and prepare documentation. Follow-up testing and inspections may be necessary to verify that required modifications are made and the system operates as required.

- Prepare the integrated test report, which outlines the test performed and the results of those tests. The integrated test report also provides the recommended periodic integrated test frequency based on their understanding and the complexity of the system.

Unfortunately, we often do not live and work in an ideal world. Currently, fire alarm commissioning rarely follows the NFPA systematic approach for a number of reasons.

The simplest reason relates to a common misunderstanding of the intended breadth of commissioning and integrated testing. Despite the consistently growing trend toward “commissioning” a building, too often system acceptance testing with the authority having jurisdiction (AHJ) is still erroneously equated to it, especially for fire protection systems. The project stakeholders simply expect that system acceptance testing performed in accordance with the system design and installation standard will suffice.

For fire protection systems, the requirement for testing of the system before receiving approval from the AHJ is a disadvantage. For many other systems, commissioning represents the inauguration of a means of evaluating and testing system performance. Commissioning means starting with a clean slate for these systems. Having an evaluation method already in place for fire alarm systems can make it harder to alter existing preconceptions to reflect the true mission of commissioning and integrated testing.

Another reason for not following this systemic approach is cost. Comprehensive commissioning and testing in any form represent a greater cost to owners than in the past. While it can be argued that the upfront cost of commissioning is defrayed by verifying that the building is operating properly and efficiently, it can still represent sticker shock to an owner. With energy efficiency and sustainability representing the vanguard of the commissioning movement, it is easy to dismiss other systems that don’t directly or noticeably contribute to these goals. The other reality in today’s marketplace is that the fire protection systems are rarely properly reviewed, coordinated, designed, and installed with an eye toward both code compliance and the best interest of the owner. The commissioning process fills that void.

Many owners or end users don’t recognize the importance of the fire alarm system and its interaction with various other systems, thus it is treated as a single system that can be easily commissioned at the end of a project. This can lead to one of two scenarios:

- The fire alarm system is commissioned as a standalone system and its integration with other systems is never evaluated.

- Recognition of its role as a central hub for several systems occurs late in design or into construction, and an abbreviated commissioning process is administered.

Neither scenario is beneficial to creating a fully integrated and functional building, though scenario two at least offers the potential to achieve commissioning goals at the end of the project. In fact, the second scenario probably represents the current standard for commissioning a fire alarm system, at least based on the bulk of our experience. Initiating commissioning efforts near the end of design or during the construction phase of a project is normal, and it comes with challenges and the potential for significant discomfort for both the design and construction teams. While the systematic approach of the NFPA documents may appear to be excessive to some, it can alleviate a lot of issues and apprehension at the end of a project.

http://www.csemag.com/single-article/integrating-commissioning-testing-for-fire-alarm-systems/a52fdd82ef05063868a3209b22c3c8a3.html

Written by: Joshua Greene, PE, Jensen Hughes, Framingham, Mass.

01/30/2017