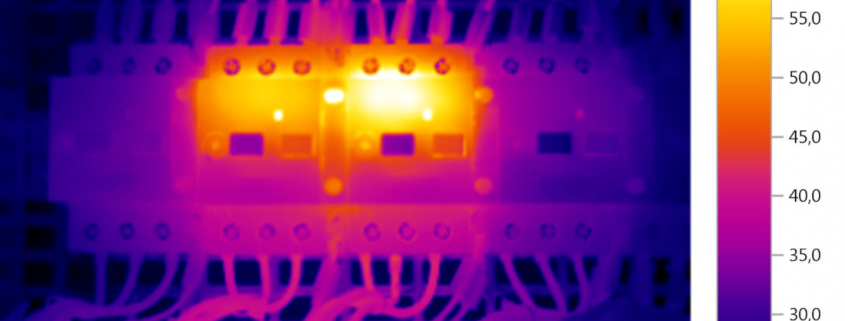

INFRARED THERMOGRAPHY: EARLY DETECTION PREVENTS DOWNTIME

Thermography has been utilized a key early detection tool for many years over a wide variety of industries. Since the 1980’s, the use of this technology in the commercial building sector has grown due to its unrivaled ability to identify vulnerable electrical equipment or connections, which if left undetected, would result in costly repairs and operational downtime. Skilled thermographers can provide valuable site assessments on nearly every building component that can be utilized by facility management teams to create effective preventative maintenance programs. In some cases, awareness of this proven technology has been realized by insurance underwriters through reduced premium offerings to customers who pursue electrical thermographic surveys.

Choosing the right team to perform these non-invasive surveys is the first step in realizing the benefit of this time proven service. Improper thermal tuning may lead to misinterpretation of thermographic images and can be a costly mistake leading to premature replacement reports or overlooked subtle differences that can reduce the effectiveness of a program. FXB combines the extensive building system knowledge of professional engineers with the thoroughness of certified field technicians to oer turnkey solutions which can satisfy any thermal imaging needs.